American Custom Drying is a leading spray drying manufacturer, operating more than 60 years. Our dedication to your success drives us to produce the most economical and highest quality products to meet your specifications. With our team of industry experts, we promise to provide you the best service and help your business grow.

Richard Shipley, a chemist with a strong interest in milk proteins, started American Casein Company

The company installed its first tower spray dryer, began manufacturing various caseinates.

The second tower spray dryer was installed and 100,000 gallons of on-site silo storage was added. The expansion of manufacturing capabilities continued with the installation of additional blending and milling capabilities.

A new specialty dryer was installed and the second tower dryer was upgraded. Additional batching room

Wet-batching capabilities were expanded and second powder processing facility opened in NJ.

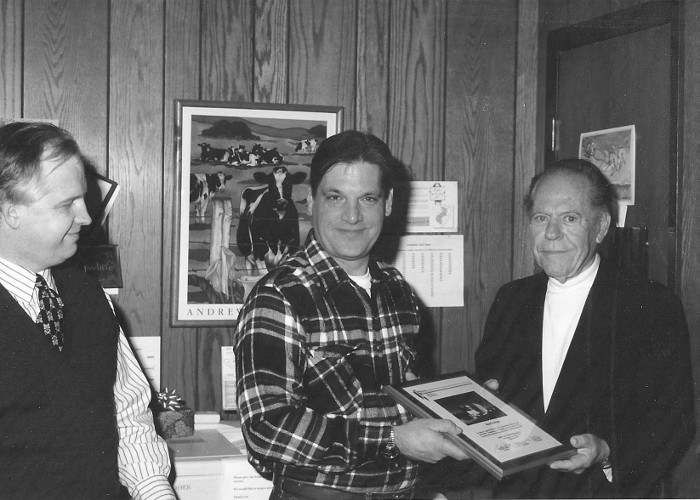

Shipley’s grandson Adam Cabot became the CEO of the company. Major facility and equipment upgrades were done including new PLCs, improved wet-batching controls, new powder conveying equipment along with new walls, floors and roofs for the original drying room. The company became SQF certified further expanding its footprint into food grade processing.

The business pivoted toward specialty ingredient processing with the installation of a fourth dryer and third batch room. A dedicated R&D dryer was added. Expanded upon warehousing with additions to flagship building and by adding an additional warehouse.

American Custom Drying opened our second facility, located in Mountain Top, PA in 2022.

READY TO TRANSFORM YOUR LIQUID TO POWDER?

American Custom Drying

109 Elbow Lane

Burlington, NJ 08016

Phone: 609-326-6000

Fax: 609-387-7204

Email: info@acdprocessing.com

2023 © American Custom Drying - All Rights Reserved.

Adam Cabot brings over 20 years of leadership experience to American Custom Drying. After working in Private Equity on investments in Manufacturing, Real Estate, Telecoms and Banking, Cabot joined ACD in 2011. As the CEO, he has focused on redefining ACD from a commodity toller into a specialty ingredients toller with multiple locations. When not working to grow ACD, Adam spends his time running, golfing and spending time with his wife and three children.

Bob Slade brings over 30 years of experience in mechanical engineering, manufacturing, capital project management, and operational leadership to American Custom Drying (ACD). Since joining ACD in 2013, Bob has led engineering and production efforts at the New Jersey facility. Most recently, he has also applied his varied experience to strategic growth opportunities, including the expansion of ACD’s spray drying and powder processing capabilities. Bob has a Bachelor’s Degree in Mechanical Engineering and an MBA with a concentration in Finance. Outside of work, Bob enjoys spending time with his wife and daughter, golfing, and relaxing at the Jersey shore.

Mike joined our team in the summer of 2023. Holding a bachelor’s degree in accounting from La Salle University, Mike brings 16 years of finance experience within the manufacturing industry. As Controller, Mike oversees team finances, treasury activities and provides clients with personalized financial solutions. Outside of work, Mike enjoys spending time with his family, the beach and golf.